TQC(Total quality control)

System for optimizing production based on ideas developed by Japanese industries from the 1950s on. The system, which blends Western and Eastern ideas, began with the concept of quality circles, in which groups of 1020 workers were given responsibility for the quality of the products they produced. It gradually evolved into various techniques involving both workers and managers to maximize productivity and quality, including close monitoring of staff and excellent customer service. The concept of kaizen, the notion that improvement must involve all members of a company, is central to TQC. production management.

TQC and TQM

Total Quality Control (TQC) is not a new concept, nor was it invented by the Japanese. The orginal book entitled ‘Total Quality Control’ was written by Armand Feigenbaum, in 1951, where he noted the universal importance of quality to customers:

“Quality is the basic customer decision factor for an explosively growing number of products and services today–whether the buyer is a housewife, an industrial corporation, a government agency, a department store chain or a military defense program.”

As a result, he proposed that quality be move out of the factory floor, where it mostly lived then, and into the rest of the company. In his words (and his italics):

“Quality is in its essence a way of managing the organization.”

It was thus an extension of Quality Control (QC) to the totality of the whole company.

The term TQC was not, however, a term that sat well with American management, so some kind soul converted it into TQM, or Total Quality Management.BS.4778:Part 2(1991) described it as:

‘A management philosophy embracing all activities through which the needs and expectations of the customer and the community and th4 objectives of the organization are satisfied in the most efficient and cost effective way by maximizing the potential of all employees in a continuing drive for improvement.’

TQM was well accepted and became a very popular worldwide fad. However, as with most fads, the basics were sound but the implementation in the majority of companies was fundamentally flawed. So, for many firms, the round of blaming took its usual course, with most fingers pointed on the fad and any handy consultants or internal people who had nailed their colors too high on the mast.

This, of course, is excellent news for companies who are serious about quality. Whilst the benefits of a temporary quality focus fade into the cost-cutting dust, the real players will reap the real rewards.

TQC also stands for Time, Quality and Cost, three items that often traded off against one another, although with suitable attention to quality, time and cost may both be reduced.

The Eight Elements of TQM

Total Quality Management (TQM) is a management approach that originated in the 1950s and has steadily become more popular since the early 1980s. Total quality is a description of the culture, attitude and organization of a company that strives to provide customers with products and services that satisfy their needs. The culture requires quality in all aspects of the company’s operations, with processes being done right the first time and defects and waste eradicated from operations.

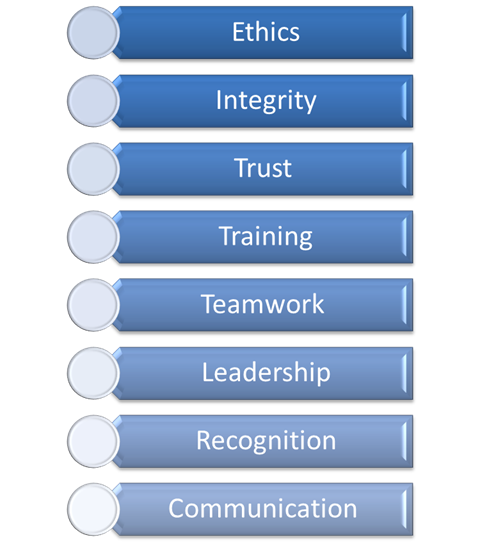

To be successful implementing TQM, an organization must concentrate on the eight key elements:

This paper is meant to describe the eight elements comprising TQM.

Key Elements

TQM House Including Eight Key ElementsTQM has been coined to describe a philosophy that makes quality the driving force behind leadership, design, planning, and improvement initiatives. For this, TQM requires the help of those eight key elements. These elements can be divided into four groups according to their function. The groups are:

I. Foundation – It includes: Ethics, Integrity and Trust.

II. Building Bricks – It includes: Training, Teamwork and Leadership.

III. Binding Mortar – It includes: Communication.

IV. Roof – It includes: Recognition.

I. Foundation

TQM is built on a foundation of ethics, integrity and trust. It fosters openness, fairness and sincerity and allows involvement by everyone. This is the key to unlocking the ultimate potential of TQM. These three elements move together, however, each element offers something different to the TQM concept.

1. Ethics – Ethics is the discipline concerned with good and bad in any situation. It is a two-faceted subject represented by organizational and individual ethics. Organizational ethics establish a business code of ethics that outlines guidelines that all employees are to adhere to in the performance of their work. Individual ethics include personal rights or wrongs.

2. Integrity – Integrity implies honesty, morals, values, fairness, and adherence to the facts and sincerity. The characteristic is what customers (internal or external) expect and deserve to receive. People see the opposite of integrity as duplicity. TQM will not work in an atmosphere of duplicity.

3. Trust – Trust is a by-product of integrity and ethical conduct. Without trust, the framework of TQM cannot be built. Trust fosters full participation of all members. It allows empowerment that encourages pride ownership and it encourages commitment. It allows decision making at appropriate levels in the organization, fosters individual risk-taking for continuous improvement and helps to ensure that measurements focus on improvement of process and are not used to contend people. Trust is essential to ensure customer satisfaction. So, trust builds the cooperative environment essential for TQM.

II. Bricks

Basing on the strong foundation of trust, ethics and integrity, bricks are placed to reach the roof of recognition. It includes:

4. Training – Training is very important for employees to be highly productive. Supervisors are solely responsible for implementing TQM within their departments, and teaching their employees the philosophies of TQM. Training that employees require are interpersonal skills, the ability to function within teams, problem solving, decision making, job management performance analysis and improvement, business economics and technical skills. During the creation and formation of TQM, employees are trained so that they can become effective employees for the company.

5. Teamwork – To become successful in business, teamwork is also a key element of TQM. With the use of teams, the business will receive quicker and better solutions to problems. Teams also provide more permanent improvements in processes and operations. In teams, people feel more comfortable bringing up problems that may occur, and can get help from other workers to find a solution and put into place. There are mainly three types of teams that TQM organizations adopt:

A. Quality improvement teams or excellence teams (QITs) – These are temporary teams with the purpose of dealing with specific problems that often recur. These teams are set up for period of three to twelve months.

B. Problem solving teams (PSTs) – These are temporary teams to solve certain problems and also to identify and overcome causes of problems. They generally last from one week to three months.

C. Natural work teams (NWTs) – These teams consist of small groups of skilled workers who share tasks and responsibilities. These teams use concepts such as employee involvement teams, self-managing teams and quality circles. These teams generally work for one to two hours a week.

6. Leadership – It is possibly the most important element in TQM. It appears everywhere in organization. Leadership in TQM requires the manager to provide an inspiring vision, make strategic directions that are understood by all and to instill values that guide subordinates. For TQM to be successful in the business, the supervisor must be committed in leading his employees. A supervisor must understand TQM, believe in it and then demonstrate their belief and commitment through their daily practices of TQM. The supervisor makes sure that strategies, philosophies, values and goals are transmitted down through out the organization to provide focus, clarity and direction. A key point is that TQM has to be introduced and led by top management. Commitment and personal involvement is required from top management in creating and deploying clear quality values and goals consistent with the objectives of the company and in creating and deploying well defined systems, methods and performance measures for achieving those goals.

III. Binding Mortar

7. Communication – It binds everything together. Starting from foundation to roof of the TQM house, everything is bound by strong mortar of communication. It acts as a vital link between all elements of TQM. Communication means a common understanding of ideas between the sender and the receiver. The success of TQM demands communication with and among all the organization members, suppliers and customers. Supervisors must keep open airways where employees can send and receive information about the TQM process. Communication coupled with the sharing of correct information is vital. For communication to be credible the message must be clear and receiver must interpret in the way the sender intended.

There are different ways of communication such as:

A. Downward communication – This is the dominant form of communication in an organization. Presentations and discussions basically do it. By this the supervisors are able to make the employees clear about TQM.

B. Upward communication – By this the lower level of employees are able to provide suggestions to upper management of the affects of TQM. As employees provide insight and constructive criticism, supervisors must listen effectively to correct the situation that comes about through the use of TQM. This forms a level of trust between supervisors and employees. This is also similar to empowering communication, where supervisors keep open ears and listen to others.

C. Sideways communication – This type of communication is important because it breaks down barriers between departments. It also allows dealing with customers and suppliers in a more professional manner.

IV. Roof

8. Recognition – Recognition is the last and final element in the entire system. It should be provided for both suggestions and achievements for teams as well as individuals. Employees strive to receive recognition for themselves and their teams. Detecting and recognizing contributors is the most important job of a supervisor. As people are recognized, there can be huge changes in self-esteem, productivity, quality and the amount of effort exhorted to the task at hand. Recognition comes in its best form when it is immediately following an action that an employee has performed. Recognition comes in different ways, places and time such as,

Ways – It can be by way of personal letter from top management. Also by award banquets, plaques, trophies etc.

Places – Good performers can be recognized in front of departments, on performance boards and also in front of top management.

Time – Recognition can given at any time like in staff meeting, annual award banquets, etc.

Conclusion

We can conclude that these eight elements are key in ensuring the success of TQM in an organization and that the supervisor is a huge part in developing these elements in the work place. Without these elements, the business entities cannot be successful TQM implementers. It is very clear from the above discussion that TQM without involving integrity, ethics and trust would be a great remiss, in fact it would be incomplete. Training is the key by which the organization creates a TQM environment. Leadership and teamwork go hand in hand. Lack of communication between departments, supervisors and employees create a burden on the whole TQM process. Last but not the least, recognition should be given to people who contributed to the overall completed task. Hence, lead by example, train employees to provide a quality product, create an environment where there is no fear to share knowledge, and give credit where credit is due is the motto of a successful TQM organization.

Quality Control Circle (QCC)

Quality control is a process by which organizations analyze the quality of all factors involved in the production process. Quality control is carried out internally by a team or officers, or externally by consultants or a government body to uncover defects in products.

A quality control circle is a small group of workers who come together to discuss ways of identifying, analyzing, solving, and selecting work related issues. More than 95% of work related problems can be resolved using various QC tools. Some of the tools used are the cause and effect diagram, check sheets, scatter diagram, control charts, pareto diagrams, stratification, histograms, and graphs.

For a quality control circle to be implemented the management has to be informed about the intensions of the group of workers that plan on meeting and approval must be granted by the management. A committee is set up, and persons to fill principal positions are selected. Principal members of a circle include the Facilitator, the Team leader, the Secretary, and members. After the selection process, the scope of focus point is defined and effort is channeled towards resolving issues in that sector.

Circle coordinators are trained extensively in order that they may efficiently execute their various roles. Employees are then invited to become members of the quality control circle and are trained accordingly by coordinators. The aim of the QCC is to discuss problems in the company and come up with possible solutions to those problems. Hence problems are discussed and solved systematically. It is important that practical solutions be reviewed by the company’s administration and implemented without delay.

As the circle grows, different circles emerge, and the higher a member rises, more sensitive issues are dealt with. These programs must be functional in all sectors of a company. For the circle to run efficiently, the employees have to be given the power to make decisions, and the solutions they come up with have to be implemented. The management has to approve and support the program by making time available for meetings, and if necessary, training of members. Also participation must be voluntary and team work must be present for the problems to be effectively resolved.

QC circles have the same structure of quality improvement systems like Kaizen, Six Sigma, and ISO 9000. Hence, it is important that these circles be part of the company’s total quality management (TQM) initiative.

With active quality control circles in place, there is a reduction of quality lapses due to heightened quality awareness in the company. There will be an increase in output with the elimination of certain delays due to bottlenecks which translates to a higher profit for the company.

*Qutote From ‘http://www.isixsigma.com/methodology/total-quality-management-tqm/eight-elements-tqm/”

*Qutote From “http://www.sixsigmaonline.org/six-sigma-training-certification-information/quality-control-circle-(qcc).html”

*Qutote From “http://syque.com/improvement/TQC.htm”