Lean manufacturing Glossary

A

ABC production analysis

accumulation

andon

apparent efficiency vs true efficiency

auto eject

B

C

converting internal set up elements to external

D

dropper

※the name of the automatic stopping device for each warp thread of the auto loom invented by by Mr. Sakichi Toyoda.

E

F

G

H

I

J

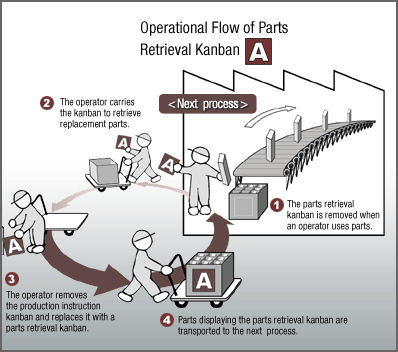

K

L

local efficiency vs total productivity

M

mizusumashi or material handler

N

O

Overall Equipment Effectiveness (OEE)

P

poka yoke

process capacity sheet

production analysis board

production kanban

pull system

Q

R

right sized equipment, right sized tooling

S

setup reduction

seven wastes

seven major losses in machinary

skills training matrix board

SMED (single Minute exhange of Die)

Standard in process sotock or standard inventory

Standardized Work

Standardized Work Chart

Standardized Work combination table

T

Toyota Production System

TPM (Total Productive Maintenance)

TPS (Toyota Production System)