TPM (Total Productive Maintenance)

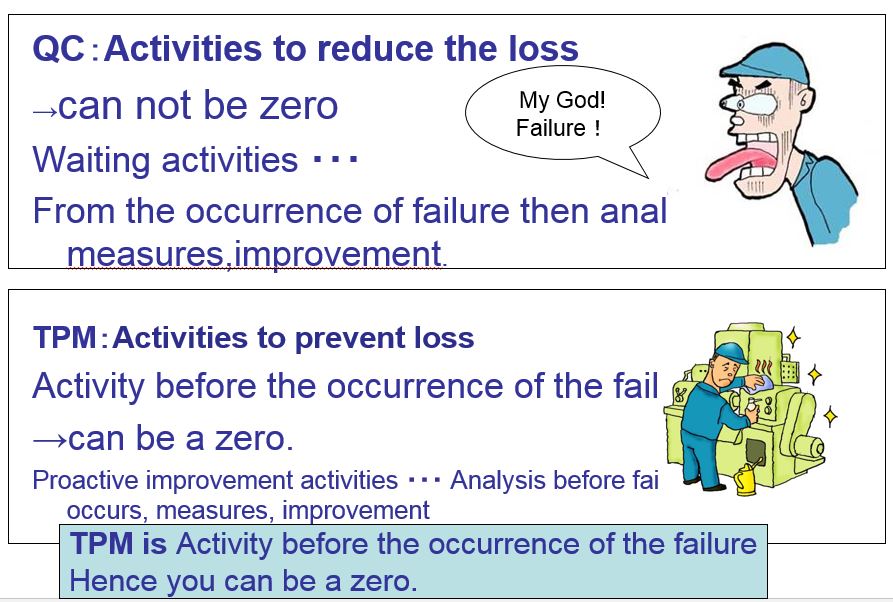

・ Establishing a corporate culture that will maximize production

system effectiveness,

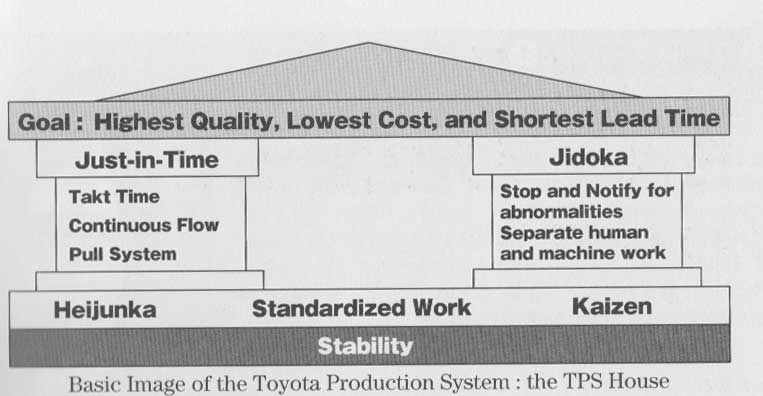

・ Organizing a practical shop-floor system to prevent losses before they occur throughout the entire production system life cycle, with aview to achieving zero accidents, zero defects and zero breakdowns,

・Involving all the functions of an organization including production,development, sales and management

・ Involving every employee, from top management down to front-line operators, and

・ Achieving zero losses through the activities of “overlapping small groups.

TPM Philosophy

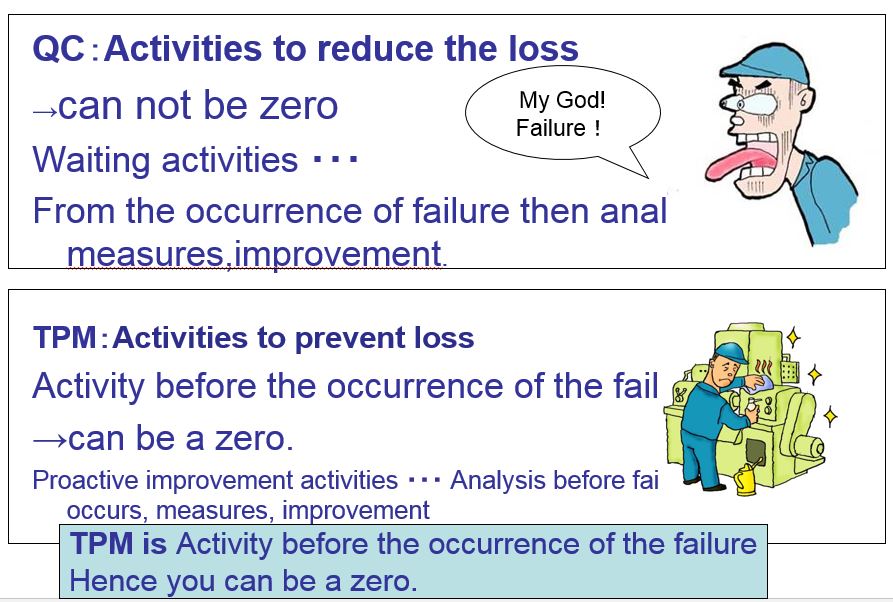

QC:Activities to reduce the loss

→can not be zero

Waiting activities ・・・

From the occurrence of failure then analysis, measures,improvement.

TPM:Activities to prevent loss

Activity before the occurrence of the failure

→can be a zero.

Proactive improvement activities ・・・ Analysis before failure occurs, measures, improvement

Reference site:Chap1 Basic education of TPM

Comments