- Kobetsu-kaizen for production efficiency

- Improvement of zero failure

- Thinking reduction of failure

- Four phases to achieve zero failures

- Five measures to achieve zero failures

- Improvement of the setup

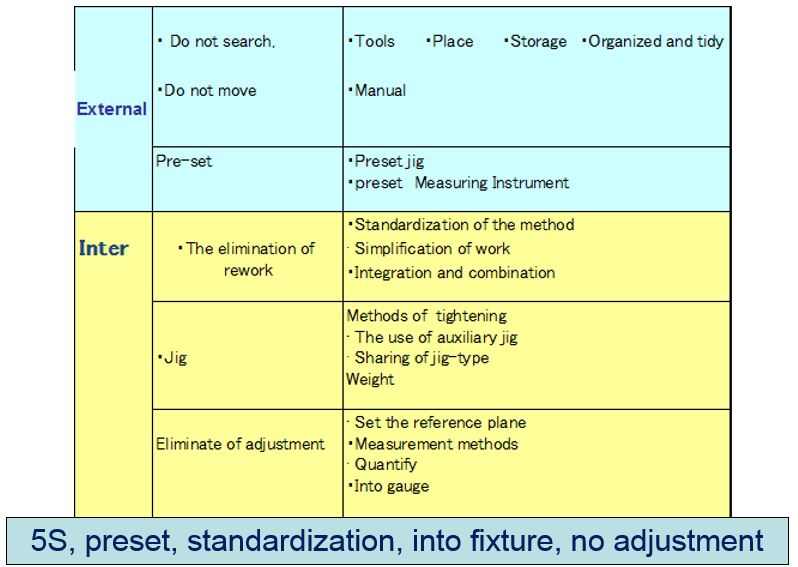

- Viewpoint Improvement of setup

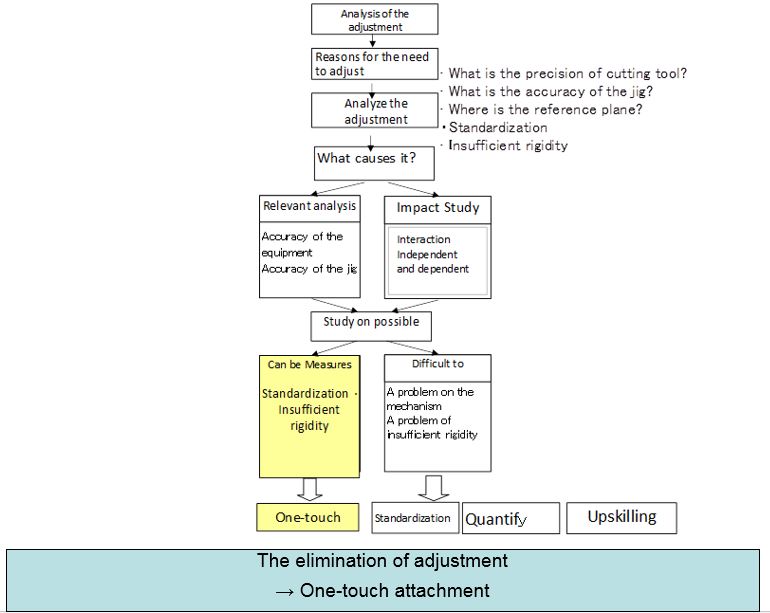

- One-touch attachment and Analysis of adjustment

- Improvement of cutting blade change loss

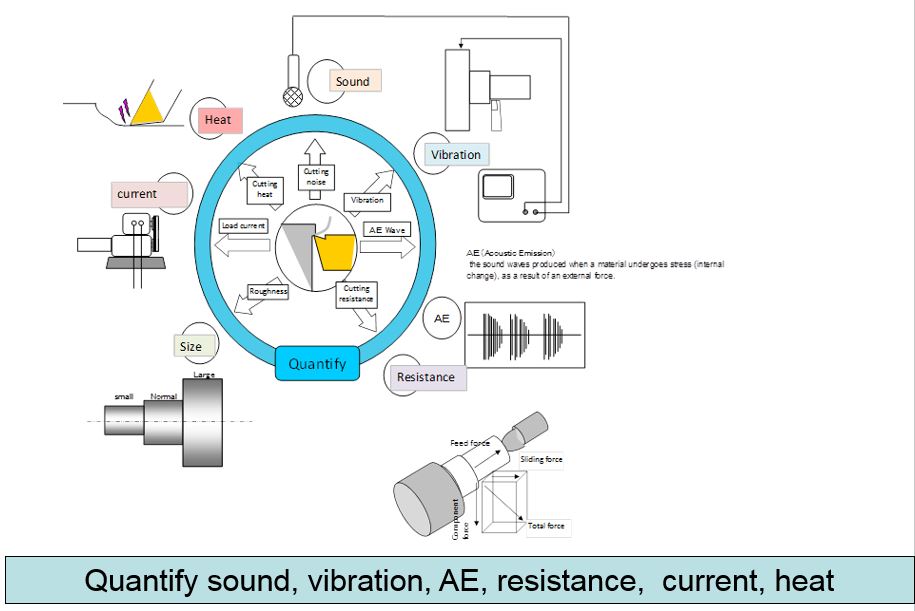

- Detection parameters of the cutting tool life

- Improvement of start up

- Improvement Way of start up

- Improvement of Minor stoppage losses

- Improvement Way of Minor stoppage losses

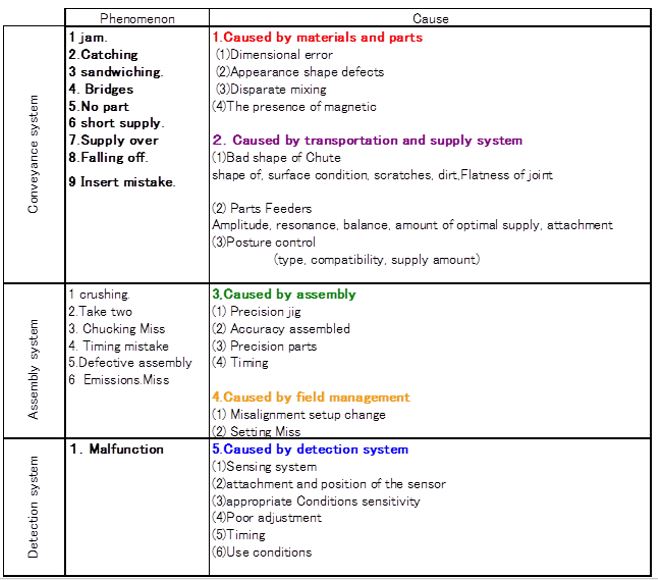

- Classification of phenomenon and Classification of causes

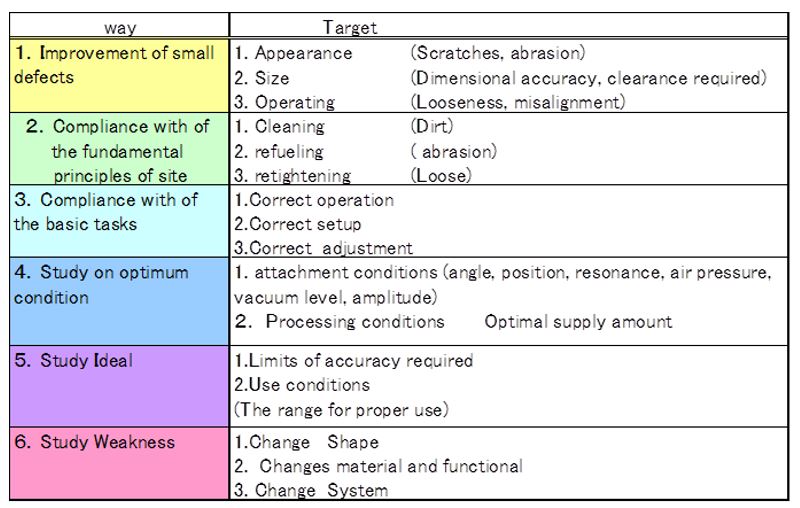

- Approch of Improvement of Minor stoppage

- Improvement of Speed losses

- How to improve the speed loses

- Improvement of Yield losses

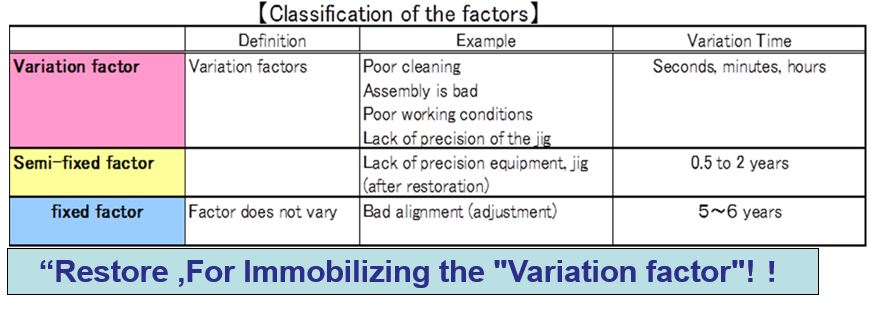

- How to to reduce chronic defects

- Principle of improvement

- Share SlideShare

Kobetsu-kaizen for production efficiency

“Kobetsu-Kaizen” refers to the “individual improvement for further efficient production systems.” It means efforts to select model equipment or a model line and to challenge the target of zero losses through project team

activities according to improvement themes.

“Kobetsu-Kaizen” takes the form of activities through project teams composed of managerial staff members and through small workshop groups.

The procedures for the implementation of “Kobetsu-Kaizen” by managerial stall members are as follows:

Model equipment or a model line should be chosen.

[2] Organization of a project team

A team of several members should be organized, with the line manager in

charge of the model equipment serving as its leader.

[3] Grasping and confirmation of 16 major losses

[4] Decision on the theme and preparation of a promotion program

[5] “Kobetsu-Kaizen” project activities

For these activities, failure analysis methods and IE methods should be

utilized. For chronic losses, PM analysis should be applied.

[6] Standardization and horizontal evolution should be completed for enhancement of OEE

Improvement of zero failure

Common challenges related to failure

(1) No interest production Section

・ The worker is not anything other than work

・ For safety reasons, worker does not touch the equipment

・ There is no provision

Workers just do not know how to Maintenance If Teach Maintenance to Wokers ,They can .

(2) Failure analysis is poor

・They have not drawn broken parts

・ They dose not have to disassemble the defective part

・They only exchange parts

・No relapse prevention

Maintenance personnel does not understand the function of the parts They does not understand Why-Why analysis

(3) Maintenance system is incomplete

・Judgment standard ,method of inspection , inspection points is incomplete

・Defective Maintenance schedule

・ Record system of failure

(4) Predictive maintenance is poor

・Periodically measuring equipment to determine the abnormality

・ Precision diagnosis ・・・

Measure vibration, current load, timing, operating time, sound, etc and then understand the change point

If there is no data management can not be right!

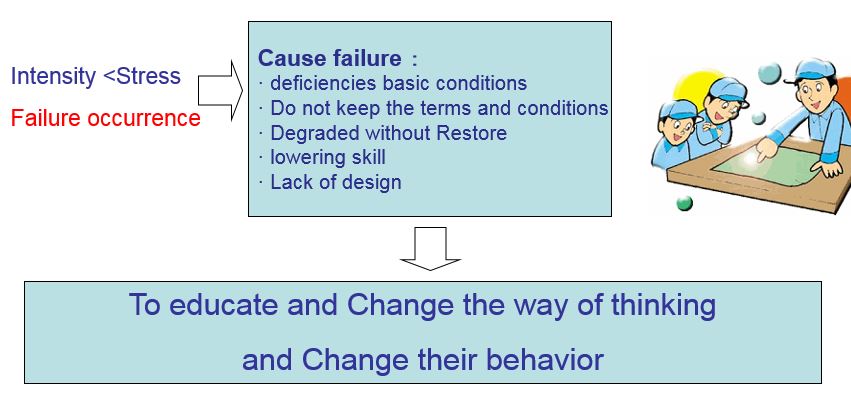

Thinking reduction of failure

(1) Classification of failure

・failure Classified simple and complex then Give priority to simple failure

・ Method of stratified ・・・Mode causes / line/Occurrence location

(2) Failure analysis

・Stress on the equipment

→ Electric or mechanical stress, temperature, humidity, dust, vibration,

To educate and Change the way of thinking and Change their behavior

Four phases to achieve zero failures

A short-term and simultaneous implementation of the five measures for zero breakdowns is unlikely to progress smoothly. It is more effective to divide enforcement of the measures into four phases and implement them one by one under a plan. Through these steps, steady approach to zero failures will become possible.

The four phases and principal themes of individual themes are as follows:

~ Phase 1: To reduce dispersion of MTBF — mean time between failures.

Repair of previous uncovered but unamended degradation to restore the original conditions, preparation of basic conditions, and

prevention of artificial machine deterioration through observance of usage conditions.

– Phase 2: To extend inherent service life.

Improvement of design shortcomings (corrective maintenance),prevention of random failure occurrences due to operation or repair errors, and restoration by fixing external appearance deterioration.

– Phase 3: To periodically repair deterioration to restore original conditions.

Regular deterioration repair to restore the original conditions

periodic maintenance: TBM), and grasping of abnormal symptoms

of internal deterioration based on the five senses.

– Phase 4: To foresee the service life.

Prediction of the service life based on condition diagnosis

techniques (predictive maintenance: CBM), and technological

analysis of catastrophic failures.

Five measures to achieve zero failures

Failures represent only the tip of the iceberg, so to speak. The leaving of

latent defects below the “water surface” causes failures.

Methods for uncovering such latent defects and preventing failures are the

“five measures to achieve zero failures, “and they are as follows:

[1] Put basic conditions in place:

Keeping of basic conditions for equipment, i.e., enforcement of cleaning,oiling, and retightening (of bolts and nuts).

l2] Abide by operational conditions:

Observance of the specified operational conditions of the equipment, such

as pressure, temperature, speed, and flow rate.

[3] Restore original functions by fixing deterioration:

The prevention of forced deterioration of quipment is possible by preparing basic conditions and abiding by usage conditions. Even so,natural deterioration, such as wear, corrosion, fatigue, and declining insulation, inevitably occurs. Therefore, such deterioration should not be left unattended but corrected to restore the original conditions.

l4] Improve design weaknesses:

Only repeating correction of deterioration cannot lead to progress. To begin with, deterioration may be accelerated due to material selection

errors or structural defects during design stage. Such design shortcomings must be rectified (this is corrective maintenance).

‘ l5] “Improve skills:

Improvement of the setup

This is one of the seven major losses that impede equipment operations and refers to the time lost from the termination of the production of a present item until the good-quality manufacturing of the next item subsequent to setup and adjustment.

The setup here means a series of work:

removal of jigs/tools upon the completion of the on-going production, clearing up, cleaning; preparation,attachment, adjustment, and measurement of jigs/tools required for the next item and manufacturing of non-defective products.

There remain many issues to be addressed to shorten the time spent on ‘internal setup’ (setup during machine stoppage) and ‘external setup’ (setup without machine stoppage) based on IE approach.

Adjustment means the following:

[1] Measures to be taken to seek the optimum solutions or values to attain some purpose; for instance, the procedures to put quality within

designed values

(1) Organize and tidy

・ Management position of tooling

・ Do not search, do not move

(2) Clarification External setup and Inter setup

・ Study Elimination of work-

・ Review of work procedures

(3)Study External setup to Inter setup

・Preset(Pre-assembled)

・ Sharing of jig and Exchange one-touch

・ Changes the adjustment to External setup

・Using the auxiliary jig・・・The elimination of adjustment

(4) Study procedures of Inter setup

・Study on method of fixation Screw fixing → Hydraulic

・ One worker → Two worker Time savings

(5) The elimination of adjustment

· The purpose of the adjustment

① positioning

② centering

③ the correct dimensions

④ timing

⑤ balance

-Cause of the adjustment

① cumulative error

② shortage standardization

③ shortage rigidity

Analysis of adjustment

Study the one-touch setup

Viewpoint Improvement of setup

5S, preset, standardization, into fixture, no adjustment

One-touch attachment and Analysis of adjustment

The elimination of adjustment→ One-touch attachment

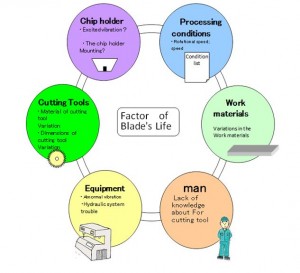

Improvement of cutting blade change loss

(1)The life of the cutting tool

・Shape and material of the cutting tool

· Cutting conditions (cutting speed)

・Material, hardness

・requirements of Quality product

(Dimensional accuracy, surface roughness)

・Rigidity of the equipment

(2)Exchange conditions

Reason:

・Unclear Exchange standards

・Failure occurs,

Exchange without permission

(3)Inhibiting unattended operation

Reason:

・varies Quality ・Short-cutting tool life

・Occurs Minor Stoppage

(4) Reduction of cutting tool’s cost

・Storing the old chip

・ No management objectives of cost cutting tool

・ Many kinds of cutting tool

・Management chip is loose

・ No historical record use of a chip

・ No Management abrasion of the chip

(Can be use but exchange can not use but No exchange)

Detection parameters of the cutting tool life

Quantify sound, vibration, AE, resistance, current, heat

Improvement of start up

Start-up losses denotes the time losses and volume losses (from defects and remark) until product quality stabilizes to manufacture non-defective products even in accordance with the specified cycle time without mechanic troubles, such as minor stoppages, small troubles, and breakage of cutting blades, during

[1] start-up after periodic overhaul [shutdown maintenance] [2] start-up after downtime (long-term line stoppage) [3] start-up after holidays [4] start-up after the lunch break.At a machining shop dimension dispersions are likely to occur during the morning setup, causing frequent adjustments, rework due to failure to

adjustment, and breakdown of cutting blades. To prevent these, warm-up and idling operations are conducted early in the morning. The target of

start-up losses is “minimization.”

Improvement Way of start up

measure:

・Measuring temperature of the table, Main shaft, etc to stabilize.

(2) Study Material :

・Consult the manufacturer the material to minimize thermal displacement

(3) Cooling the generator

・ Cool heat by Cooling fan

(4) Automatic correction

・Automatically adjusts to predict beforehand the amount of displacement

Improvement of Minor stoppage losses

[1] In case temporary functional stoppage ensues. [2] in case the recovery of functions is made by simple fixing (elimination of abnormal work-piece and/or resetting) [3] ln case parts exchange or repair are not required. [4] Recovery time lasts from 2 or 3 seconds less than 5 minutes.Unlike failures, minor stoppage/idling losses represent a status in which the machine is subjected to either stoppage or idling due to temporary troubles; for instance, when a work-piece is clogged in the chute, idling

occurs ; or when a sensor activated because of a quality defect to cause a temporary stoppage.

These are the conditions in which the machine will revert to normal operation, if the stuck work-piece is removed, or resetting is carried out. Therefore, they are fundamentally different from machine failures.

To reduce minor stoppages, it is important to in detail analyze phenomena [or slight defects] and to thoroughly eliminate slight defects.

Improvement Way of Minor stoppage losses

Phenomenon analysis and motion analysis of workpiece:

Video recording the phenomenon of Minor stoppage , Viewpoint is movement

posture, angle, float, vibration

(2) Remediation of the defect:

Contact surface of the workpiece is key point

Improve the small defects of parts and jigs

(3)Compliance with the basic maintenance:

Cleaning, refueling, retightening

(4) Compliance with of the basic tasks:

Correct operation, setup, adjustment

(5)Study on optimum condition:

Studied the optimization of processing conditions of Parts

(6)Study Weakness:

Studied the problem of the design of equipment、parts,jigs

Classification of phenomenon and Classification of causes

Approch of Improvement of Minor stoppage

Improvement of Speed losses

One of the seven major losses impeding efficiency improvement of equipment. These losses incurred by slow machine speed are defined as

follows:

[1] Losses due to the difference between the actual speed and the design

speed (or reference speed for each product item)

[2] Losses resulting from lower design speed compared to the present technological level or desirable speed

(or ‘mission’ speed)

As an example of the former case, the cycle time is 60 seconds as reference but the actual operation cycle time is 65 seconds. There is a speed loss of 5 seconds. As an example of the latter case, the cycle time is set at 60 seconds but it could be reduced to 50 seconds through improvement based on the current technological level. There is a speed loss of 10 seconds in this case.

Aiming at speed increase would contribute to clarification of problems and

upgrading of technological levels. Therefore, the target should be to make

nit the difference between the design speed and the actual speed.

How to improve the speed loses

Study Air cut time,Idle time,Operating time,Two person work

(1)Understand the cause

To speed up For the experiment.

① Changes in Cp ?

② New bad item ?

③ The life of the cutting tool ?

④ Number of occurrences of Minor Stoppage?

⑤ Percentage occurrence of defective ?

*Examine the aggravating factors measures ahead

(2)Check the validity of the action

①Reduction of air cut time

②Reduction of idle time ③Reduction of operating time ④ Reduction of working hours by two people work

*Make improvement on equipment mechanism, component structure, timing, the cycle diagram.

Improvement of Yield losses

This refers to the volume losses resulting from differences between raw material weight and product weight, or between raw materials input and product weight.

The former represents material losses that can result from leaving too much iron cast for fear of casting shortcomings (such as sand inclusion) or from forging too thick so that it may be sufficient enough to obtain mold precision in the shaping process.

As a result of these, cutting time can be lengthened, or the service life of cutting blades shortened.

The latter represents the difference between whitewash weight, gate weight, generated burr volume and the product weight. in other words, the losses in this category result from increased burr generation due to molding precision insufficiency.

in the case of aluminum casting, this refers to the

losses representing runner weight and blur Weight.

How to to reduce chronic defects

(1)Immobilization of variable factors

factors?:Impact phenomena logically

Cause?:Which have proved to have influenced the phenomenon

Principle of improvement

Eliminate

Combine

Rerrange

Simply

Please freely utilize my Free download Illustration

pretty Aryan WOMAN factory workers

comical Aryan Gesture factory workers

Share SlideShare

TPM For lean manufacturing chp3 | kobetsu kaizen for production efficiency | lean tools