What is 5S?

5S is the name of a workplace organization method that uses a list of five Japanese words: seiri, seiton, seiso, seiketsu, andshitsuke. Transliterated or translated into English, they all start with the letter “S”. The list describes how to organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order. The decision-making process usually comes from a dialogue about standardization, which builds understanding among employees of how they should do the work.

①Seiri – the first step in making things cleaned up and organized

This “S” often translated as sort, seiri can also connote tidiness, cleaning, or separating.

Seiri is the first step in the 5S process and involves the meticulous examination of everything in the work environment. All extemporaneous materials or anything unrelated to the workplace are removed from the area. These items can be either stored for possible future use or discarded.

Not everything without an immediate use needs to be thrown out. A key to implementing seiton effectively is the creation of a “red label” zone. Items with potential future use should be red-tagged and moved to a designated area.

By removing clutter and unnecessary debris, 5S eliminates hazards in the work space. A cleaner, better functioning workspace is left.

②Seiton (Separating)

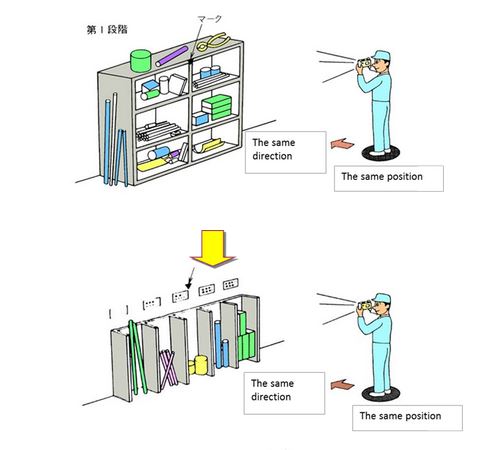

Seiton is a concept that, loosely translated, means to set things in order. This second step in the 5S process is all about efficiency and can be summarized with one sentence

Seiton consists of putting everything in an assigned area so it can be used and returned as quickly and safely as possible. Commonly used tools should be easily accessible, saving both time and effort.

Organized Tools

With color coding tools can easily be found, used, and returned to their proper places. Color coding and labeling eradicates confusion by making tools easily distinguishable by following standard color code guidelines.

③Seiso (Shine)

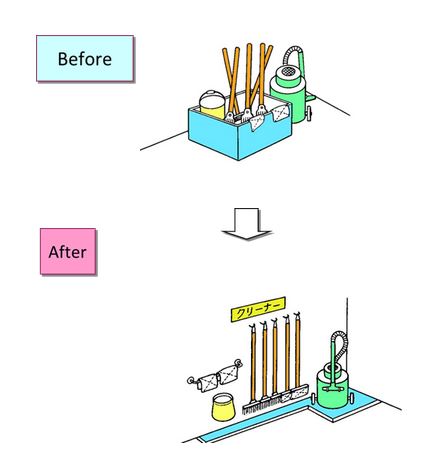

Seiso means to clean or shine. Seiso, the third step in the 5S process, focuses on cleanliness of the working environment.

Seiso champions creating a clean and neat work space. Maintenance and cleanliness become part of the everyday working routine to increase both workplace safety and longevity of tools and equipment.

Seiso focuses on not simply cleaning the working environment once, but keeping it clean every day to maintain the facility and equipment long term.

From operators to managers, making cleanliness a part of daily routine can drastically improve health, morale, and safety to a remarkable degree. Labels, explaining both how to clean something and when to do so, ensure communication and the maintenance of standard operating procedures

④Seiketsu (Standardize)

Document what needs to be done

Seiketsu loosely translates to “standardized clean-up.” Seiketsu, a single step in a transforming process, is occasionally mistaken as the entirety of the 5S methodology because it encompasses all the previous steps of cleaning up, paring down, and sustaining order.

Fostering unity of purpose, Seiketsu ensures that all work operates in a consistent and precise manner. Through standardization and increased, clear explanation, workers can accomplish their responsibilities without hesitation.

Standardizing involves constructing a consistent approach for carrying out tasks and procedures. Constant order and function are the core goals of this step.

Efficiency is increased by visual cues. Organize the work environment with clear and understandable visual cues. Color coding and the use of shapes are very effective ways to quickly achieve visual communication and obvious organization.

Shitsuke (Sustain)

Shitsuke, the final step a 5S system requires, and translates to discipline.

Shitsuke denotes a commitment to maintaining the practices of the first four S steps. It is the commitment not just to 5S methodology, but to a process of continual improvement known as kaizen. 5S can only be effective if it is a continual daily process by which all work is conducted. All strategies and methods fail without commitment.

Reinforcing and maintaining the four steps through shitsuke sustains positive growth and increased safety and efficiency.

How to proceed of 5S activities

1)Red card Strategy:

Paste to places that are not performed 5S

・Object・・・・Parts inventory, raw materials inventory

Palette, jigs, tools, chairs, equipment

Floor, aisle, shelf

2)Fixed point shooting:

Check the status of improvement by Fixed point shooting

3)Visual control

draw the outline of the tool board for Loss prevention

【Case:tool hanging Board】

4)Self maintenance:

a)Start cleaning:

cleaning equipment, and machinery by hands→ Early detection malfunction of equipment

b)Measures the occurrence of contamination:

Measures the occurrence of contamination For Prevent the scattering

c)Creating a standard refueling:

Created to Prevent the scattering of oil

”Improvement case ”

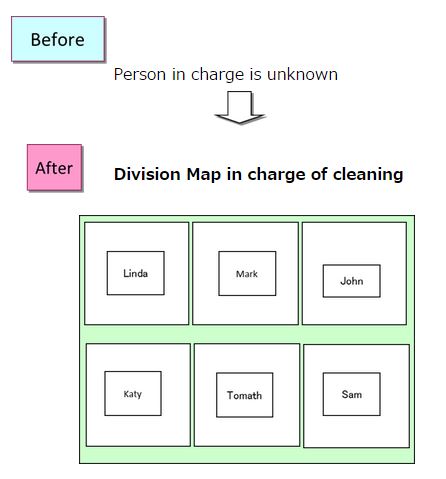

1.Clarification of the person in charge of cleaning and cleaning division

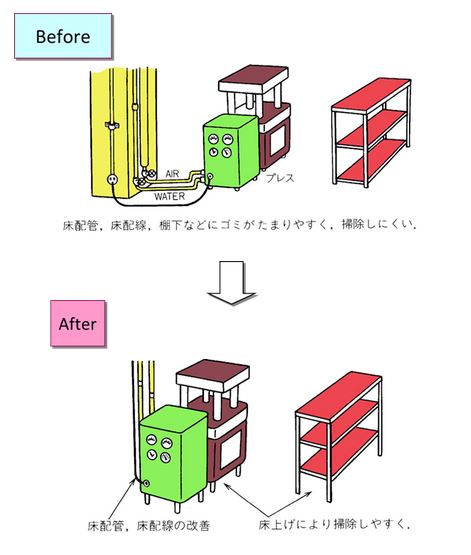

3.Change the layout easy to clean

*Quote From Wikipedia

*Quote From “http://www.graphicproducts.com/tutorials/five-s/index.php”

5s lean manufacturing Video