Visual control = mieruka

Visual control is a business management technique employed in many places where information is communicated by using visual signals instead of texts or other written instructions. The design is deliberate in allowing quick recognition of the information being communicated, in order to increase efficiency and clarity. These signals can be of many forms, from different coloured clothing for different teams, to focusing measures upon the size of the problem and not the size of the activity, to kanban andheijunka boxes and many other diverse examples. In The Toyota Way, it is also known as mieruka.

Purpose

Visual control methods aim to increase the efficiency and effectiveness of a process by making the steps in that process more visible. The theory behind visual control is that if something is clearly visible or in plain sight, it is easy to remember and keep at the forefront of the mind. Another aspect of visual control is that everyone is given the same visual cues and so are likely to have the same vantage point.

There are many different techniques that are used to apply visual control in the workplace. Some companies use visual control as an organizational tool for materials. A clearly labeled storage board lets the employee know exactly where a tool belongs and what tools are missing from the display board. Another simple example of a common visual control is to have reminders posted on cubicle walls so that they remain in plain sight. Visual signs and signals communicate information that is needed to make effective decisions. These decisions may be safety oriented or they may give reminders as to what steps should be taken to resolve a problem. Most companies use visual controls in one degree or another, many of them not even realizing that the visual controls that they are making have a name and a function in the workplace. Whether it is recognized by the name of “visual control” or not, the fact is that replacing text or number with graphics makes a set of information easier to understand with only a glance, making it a more efficient way of communicating a message.

Visual controls are designed to make the control and management of a company as simple as possible. This entails making problems, abnormalities, or deviations from standards visible to everyone. When these deviations are visible and apparent to all, corrective action can be taken to immediately correct these problems.

Visual controls are meant to display the operating or progress status of a given operation in an easy to see format and also to provide instruction and to convey information. A visual control system must have an action component associated with it in the event that the visually represented procedures are not being followed in the real production process. Therefore visual controls must also have a component where immediate feedback is provided to workers.

Objecet and Use of Visual control

【Objecet】

Make Goods

Better,Low Priced,when needed, quantity needed

【Specific Objecet】

①Quality improvement Quality control

②Cost improvement Cost Control

③Compliance with delivery Process Control

Inventory reduction

④Keep and improve of work safety Safe environment

⑤Improvement 5S and teamwork Labor control

in the workplace

⑥Maintenance and improvement of Equipment control

equipment and tooling

⑦Keep and improvement of logistics Material control

⑧Keeping the quality and Work control

improvement work

⑨Information-sharing Information Control

【Use】

①Clarifying of the problem

②Clarifying waste

③Effective control

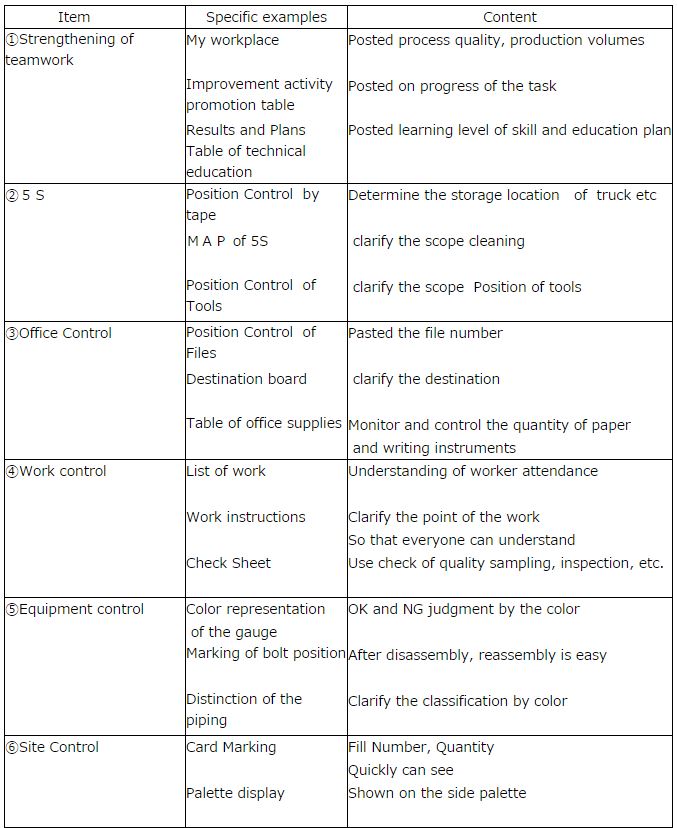

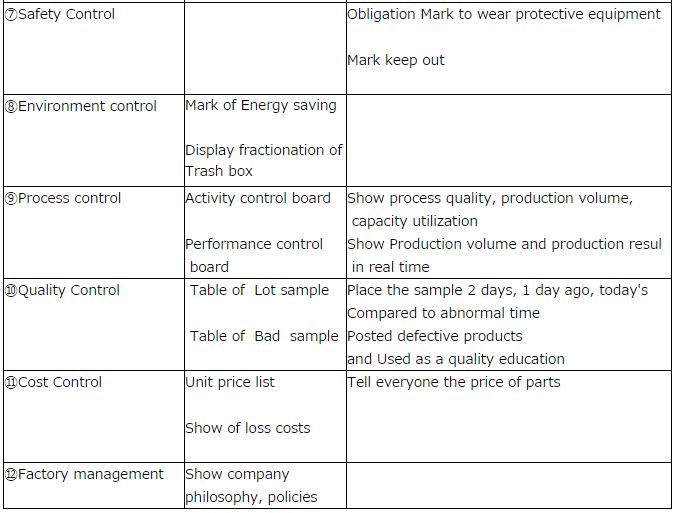

『List specific examples of Visual control』n of tools

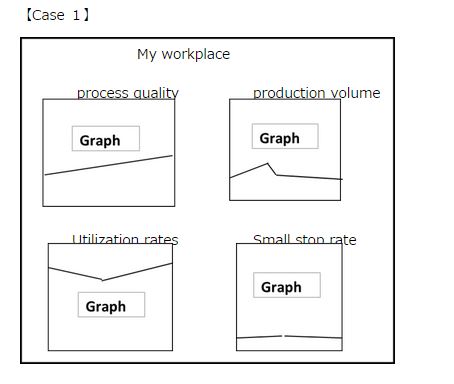

【Case 1】

My workplace

process quality production volume

Utilization rates Small stop rate

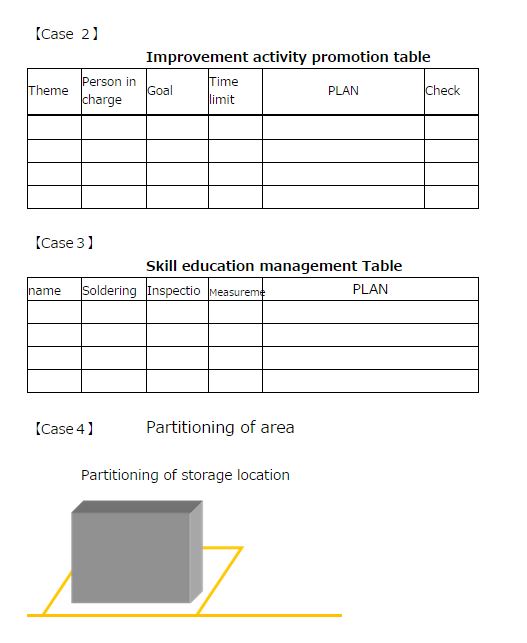

【Case 2】

Improvement activity promotion table

Theme Person in charge Goal Time limit PLAN Check

【Case3】

Skill education management Table

name Soldering Inspectio Measureme PLAN

【Case4】 Partitioning of area Partitioning of storage location

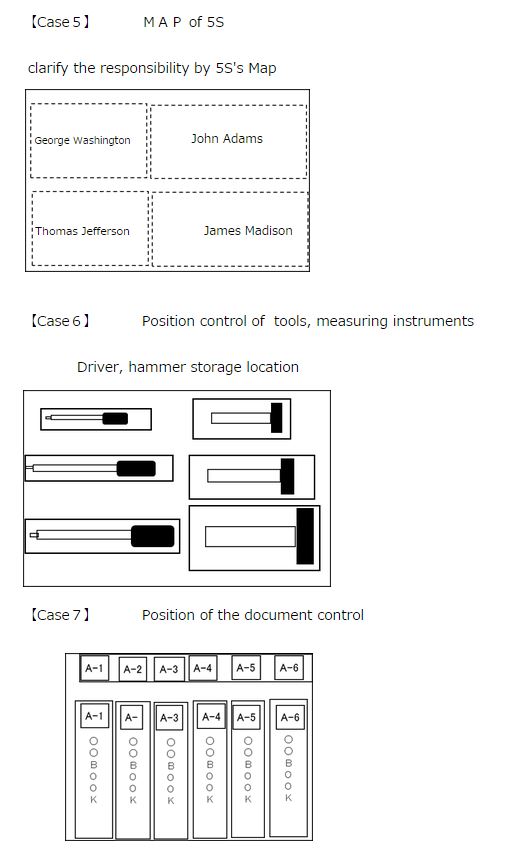

【Case5】 MAP of 5S

clarify the responsibility by 5S’s Map

George Washington John Adams

Thomas Jefferson James Madison

【Case6】 Position control of tools, measuring instruments

Driver, hammer storage location

【Case7】 Position of the document control

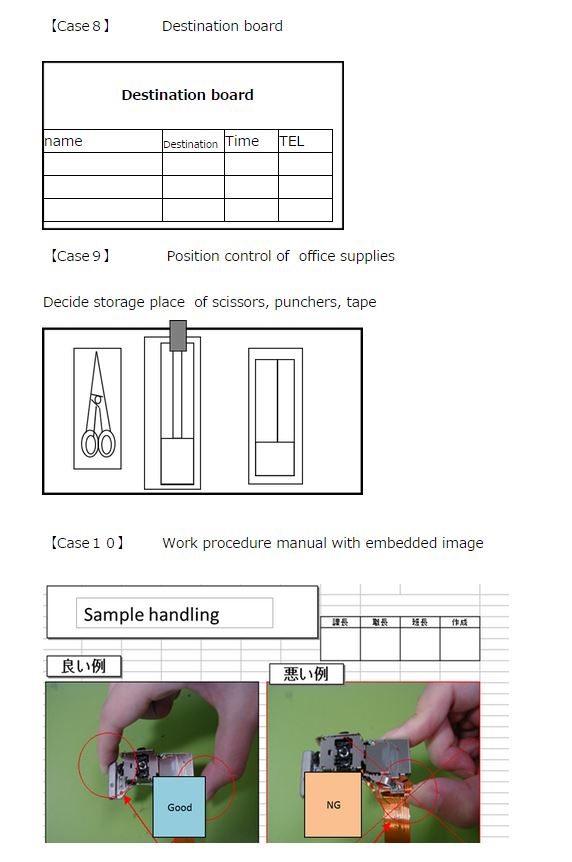

【Case8】 Destination board

Destination board

name Destination Time TEL

【Case9】 Position control of office supplies

Decide storage place of scissors, punchers, tape

50%

【Case10】 Work procedure manual with embedded image

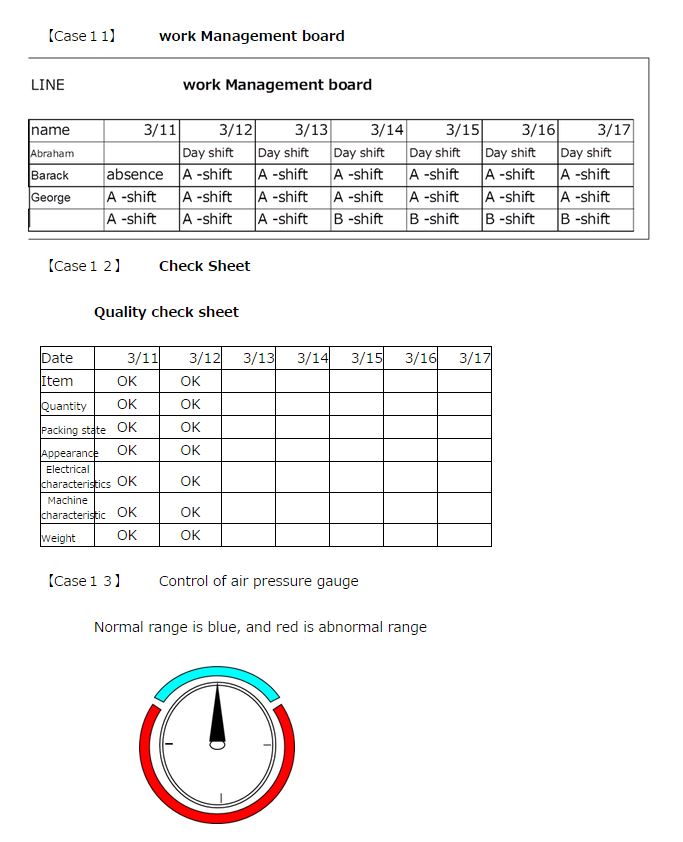

【Case11】 work Management board

【Case12】 Check Sheet

Quality check sheet

【Case13】 Control of air pressure gauge

Normal range is blue, and red is abnormal range

【Case14】 Marking of the bolt

After disassembly, reassembly is easy

【事例15】 Distinaction of the piping

【Case16】 Tested and untested

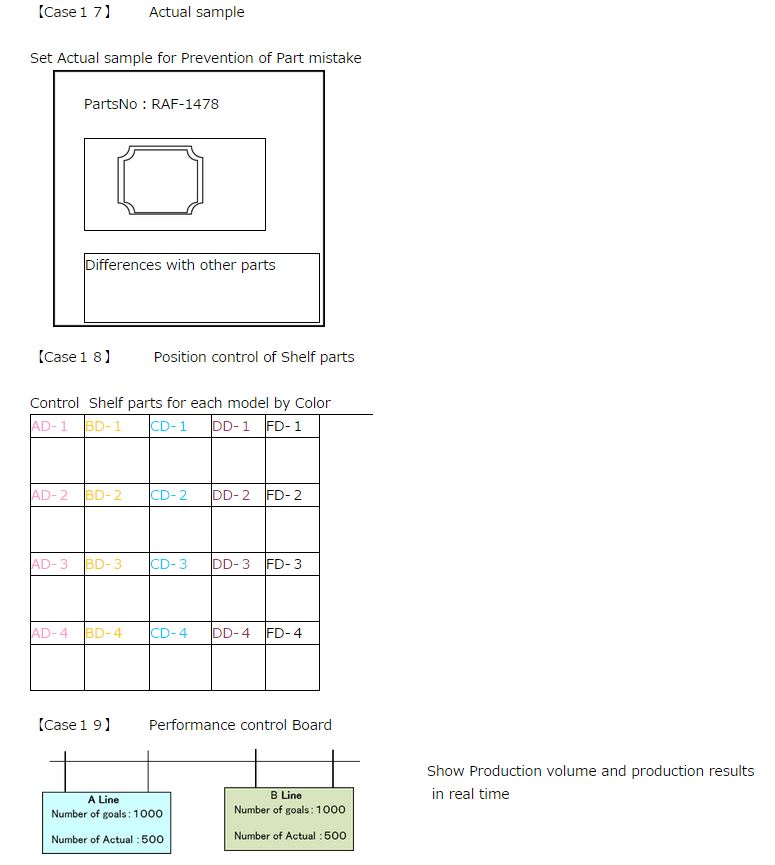

【Case17】 Actual sample

Set Actual sample for Prevention of Part mistake

Differences with other parts

【Case18】 Position control of Shelf parts

Control Shelf parts for each model by Color

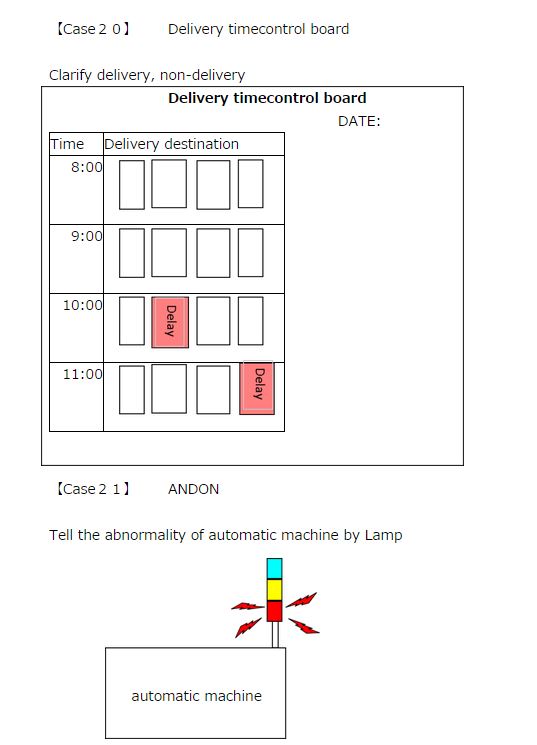

【Case19】 Performance control Board

Show Production volume and production results in real time

【Case20】 Delivery timecontrol board

Clarify delivery, non-delivery

【Case21】 ANDON

Tell the abnormality of automatic machine by Lamp

automatic machine

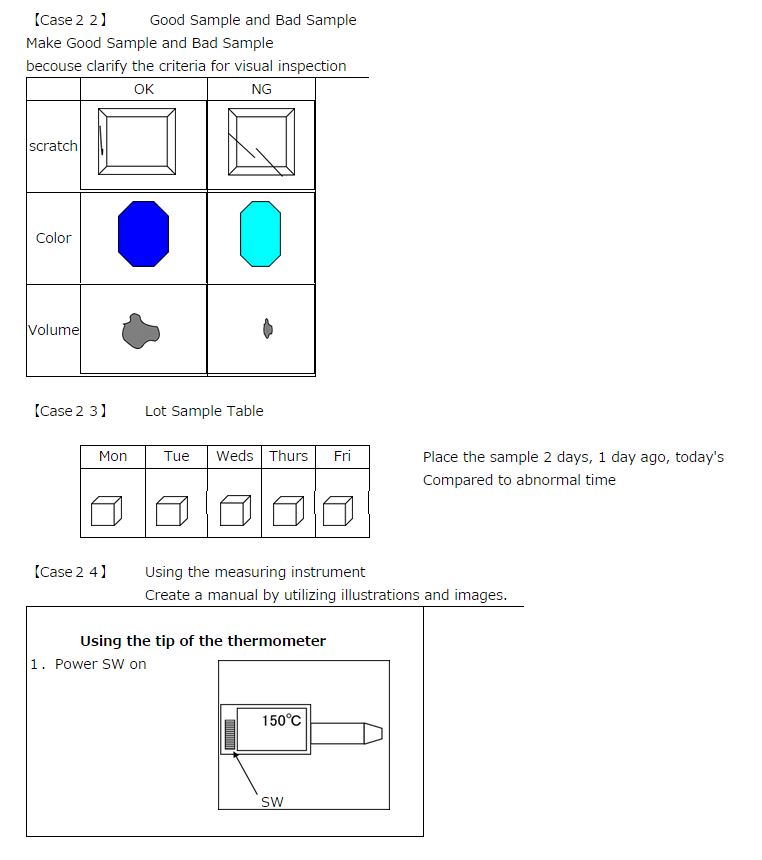

【Case22】 Good Sample and Bad Sample

Make Good Sample and Bad Sample

becouse clarify the criteria for visual inspection

【Case23】 Lot Sample Table

Mon Tue Weds Thurs Fri Place the sample 2 days, 1 day ago, today’s

Compared to abnormal time

【Case24】 Using the measuring instrument

Create a manual by utilizing illustrations and images.

Using the tip of the thermometer

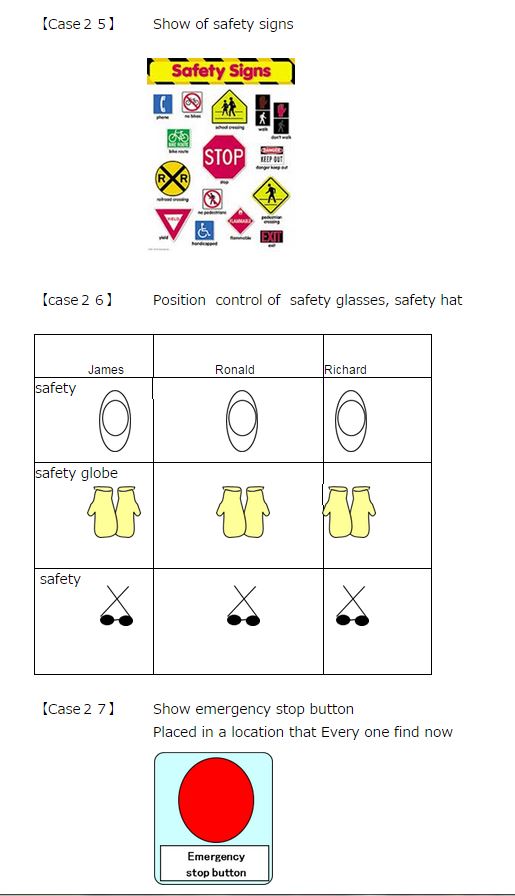

【Case25】 Show of safety signs

【case26】 Position control of safety glasses, safety hat

【Case27】 Show emergency stop button

Placed in a location that Every one find now

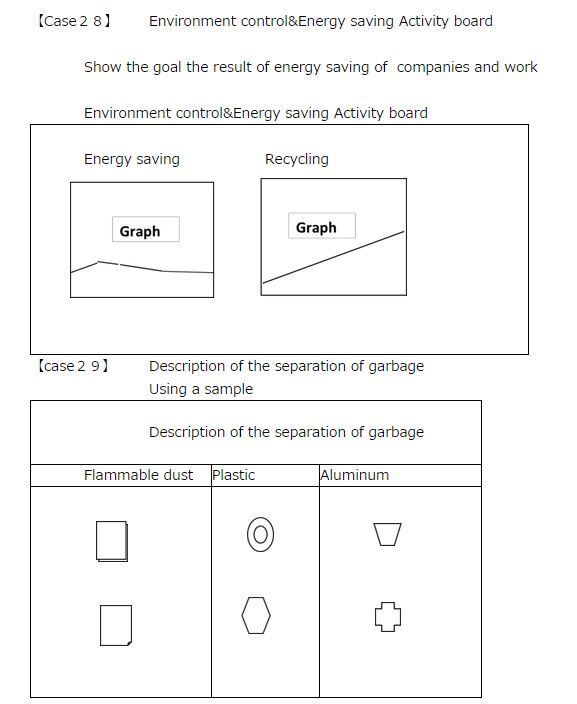

【Case28】 Environment control&Energy saving Activity board

Show the goal the result of energy saving of companies and work

Environment control&Energy saving Activity board Energy saving Recycling

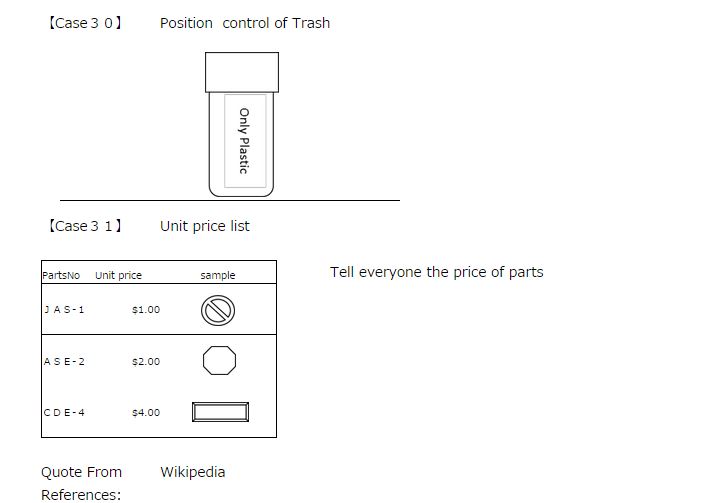

【case29】 Description of the separation of garbage

Using a sample Description of the separation of garbage

Flammable dust Plastic Aluminum

【Case30】 Position control of Trash

【Case31】 Unit price list

PartsNo Unit price sample Tell everyone the praice of parts