Quality of electronic products for the automotive

Why the Car need high level of quality ?

・Products related to human life:

For Example, when the brakes do not work, Fatal accident cloud occurre

・Brand:

Automotive electronics is a part of the car

Brand of high reliability

PL:product liability

・Product liabilityis the area of law in which manufacturers, distributors, suppliers, retailers, and others who makeproductsavailable to the public are held responsible for the injuries those products cause. Although the word “product” has broad connotations, product liability as an area of law is traditionally limited to products in the form of tangible persona

Manufacturer

Consumer

Environmental differences

・Automotive :

①Temperature (low temperature, high temperature use) -10 °~ +60 ° below zero

②Humidity (high humidity, drying)

③Vibration, shock

④Dust, rain, salt water, acid rain

・Home appliances :

Less external stress.

Maintainability and repair

・Automotive :

After separating from the car, after repair by professional, again, attached to the car.

・Home appliances :

Repair, maintenance is easy.

Process control of automotive products

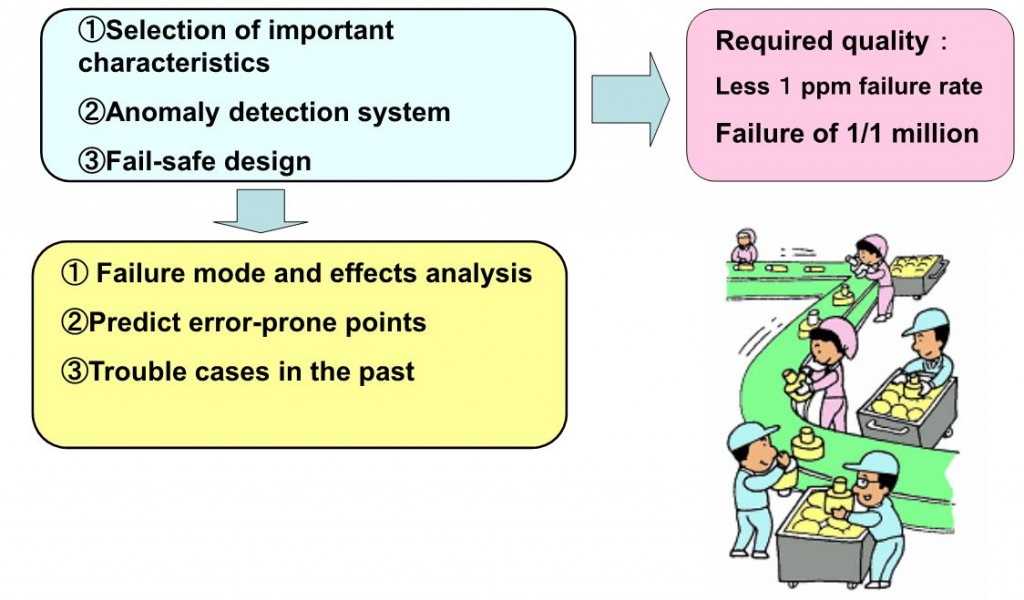

『Thinking』

①Selection of important characteristics

②Anomaly detection system

③Fail-safe design

Required quality :

Less 1ppm failure rate

Failure of 1/1 million

①Failure mode and effects analysis

②Predict error-prone points

③Trouble cases in the past

『Methed』

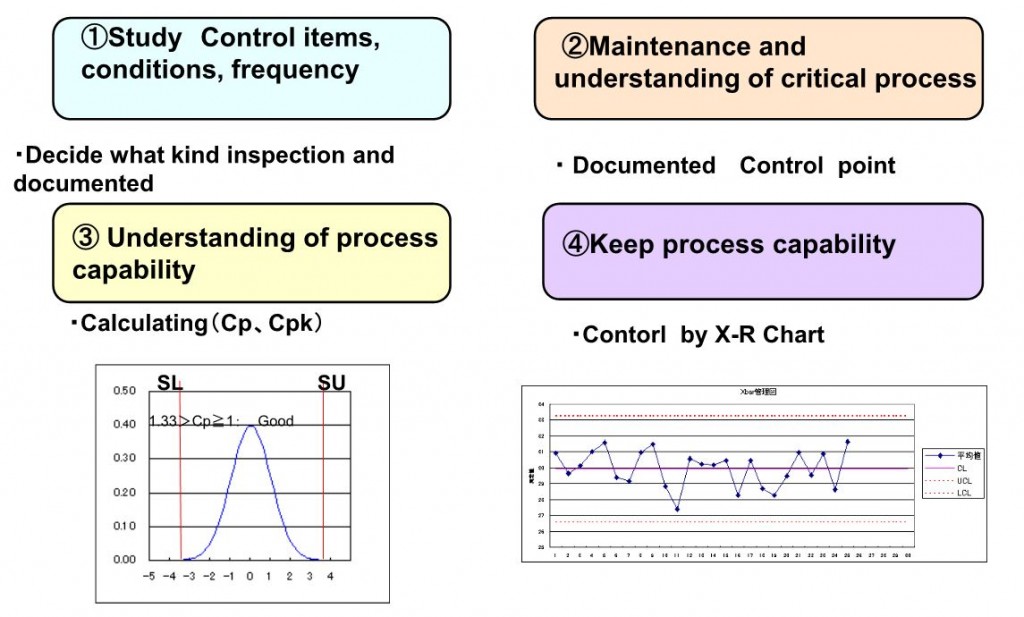

④Keep process capability

①StudyControl items, conditions, frequency

②Maintenance and understanding of critical process

③Understanding of process capability

・Decide what kind inspection and documented

・Documented Control point

・Calculating(Cp、Cpk)

・Contorl byX-R Chart

SL

SU

1.33>Cp≧1:Good

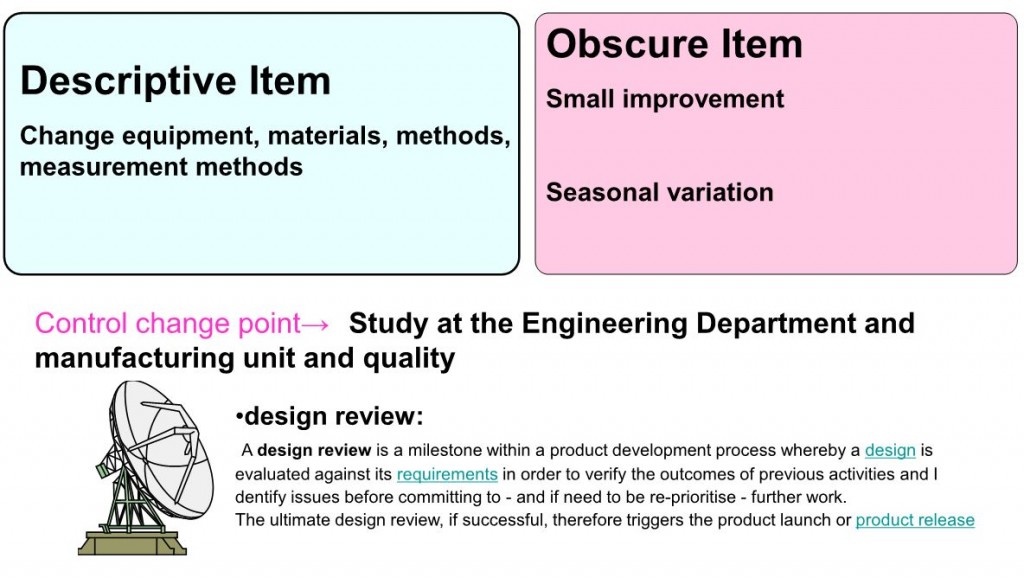

『Control change point 』

Up sensitivity of anomaly detection

Descriptive Item

Change equipment, materials, methods, measurement methods

Obscure Item

Small improvement

Seasonal variation

Control change point→Study at the Engineering Department and manufacturing unit and quality

•design review:

Adesign reviewis a milestone within a product development process whereby adesignis

evaluated against itsrequirementsin order to verify the outcomes of previous activities and I

dentify issues before committing to -and if need to be re-prioritise -further work.

The ultimate design review, if successful, therefore triggers the product launch orproduct release

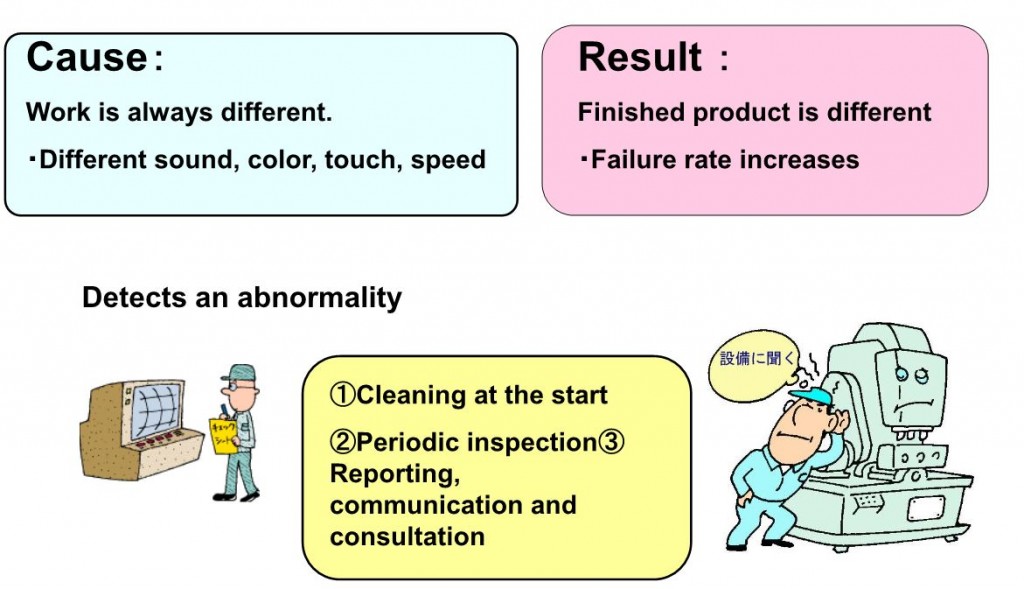

『What is Abnormal?』

Cause:

Work is always different.

・Different sound, color, touch, speed

Result :

Finished product is different

・Failure rate increases

①Cleaning at the start

②Periodic inspection③ Reporting, communication and consultation

Detects an abnormality

Challenge high quality, high reliability in Make Goods!!