What is Standardization?

Standardization or standardisation is the process of developing and implementing technical standards.

The goals of right standardization can be to help with independence of single suppliers (commoditization), compatibility, interoperability, safety, repeatability, or quality.

In social sciences, including economics, the idea of standardization is close to the solution for a coordination problem, a situation in which all parties can realize mutual gains, but only by making mutually consistent decisions. Standardization is defined as best technical application consentual wisdom inclusive of processes for selection in making appropriate choices for ratification coupled with consistent decisions for maintaining obtained standards. This view includes the case of “spontaneous standardization processes”, to produce de facto standards

Usage:

The existence of a published standard does not necessarily imply that it is useful or correct. Just because an item is stamped with a standard number does not, by itself, indicate that the item is fit for any particular use. The people who use the item or service (engineers, trade unions, etc.) or specify it (building codes, government, industry, etc.) have the responsibility to consider the available standards, specify the correct one, enforce compliance, and use the item correctly… Validation of suitability is necessary.

Standardisation is implemented greatly when companies release new products or software to market. Compatibility is important for products to be successful; many devices coming out have USB, Ethernet, or other standard types of connection. This allows consumers to use their new items along with what they already own.

By using standardisation, groups can easily communicate through the set guidelines, in order to maintain focus. The method is made to facilitate processes and tasks; this is why it interlocks with lean manufacturing.

In the context of social criticism and social sciences, standardisation often means the process of establishing standards of various kinds and improving efficiency to handle people, their interactions, cases, and so forth. Examples include formalization of judicial procedure in court, and establishing uniform criteria for diagnosing mental disease. Standardisation in this sense is often discussed along with (or synonymously to) such large-scale social changes as modernization, bureaucratization, homogenization, and centralization of society.

In the context of business information exchanges, standardisation refers to the process of developing data exchange standards for specific business processes using specific syntaxes. These standards are usually developed in voluntary consensus standards bodies such as the United Nations Center for Trade Facilitation and Electronic Business (UN/CEFACT), the World Wide Web Consortium W3C, the Telecommunications Industry Association (TIA), and the Organization for the Advancement of Structured Information Standards (OASIS).

In the context of customer service, standardisation refers to the process of developing an international standard that enables organizations to focus their attention on delivering excellence in customer service, whilst at the same time providing recognition of success through a third party organization, such as British Standards Institution (BSI). The International Customer Service Standard (TICSS) has been developed by The International Customer Service Institute (TICSI) with the objective of making it the cornerstone global standard of customer service. This standard has the status of an independent standard, managed by The International Customer Service Institute.

Standards can be:

de facto standards which means they are followed by informal convention or dominant usage.

de jure standards which are part of legally binding contracts, laws or regulations.

Voluntary standards which are published and available for people to consider for use

In general, each country or economy has a single recognized National Standards Body (NSB). Examples include ABNT, AENOR, AFNOR, ANSI, BSI, DGN, DIN, IRAM, JISC, KATS, SABS, SAC, SCC, SIS, SNZ. An NSB is likely the sole member from that economy in ISO.

NSBs may be either public or private sector organizations, or combinations of the two. For example, the three NSBs of Canada, Mexico and the United States are respectively the Standards Council of Canada (SCC), the General Bureau of Standards (Dirección General de Normas, DGN), and the American National Standards Institute (ANSI). SCC is a Canadian Crown Corporation, DGN is a governmental agency within the Mexican Ministry of Economy, and ANSI and AENOR are a 501(c)(3) non-profit organization with members from both the private and public sectors. The determinates of whether an NSB for a particular economy is a public or private sector body may include the historical and traditional roles that the private sector fills in public affairs in that economy or the development stage of that economy.

Many specifications that govern the operation and interaction of devices and software on the Internet are in use. To preserve the word “standard” as the domain of relatively disinterested bodies such as ISO, the W3C, for example, publishes “Recommendations”, and the IETF publishes “Requests for Comments” (RFCs). These publications are sometimes referred to as being standards. Drafts and working documents should not be considered as formal published standards.

In a military context, standardisation can be defined as: The development and implementation of concepts, doctrines, procedures and designs to achieve and maintain the required levels of compatibility, interchangeability or commonality in the operational, procedural, material, technical and administrative fields to attain interoperability.

Note: there are at least four levels of standardisation: compatibility, interchangeability, commonality and reference. These standardisation processes create compatibility, similarity, measurement and symbol standards. Standardisation in the context of supplies and materials management it covers the aspect of, any item of no use in the company must not be bought or made. The make or buy also outlines the standardisation process, where bolts can be used, screws might substitute the bolts so finally that is a standard approach.

Historically important standards

Standards became highly important during the Industrial Revolution with the need to make interchangeable parts. Some important historical standards included:

Sizes for screws, nuts bolts and other threaded fasteners were first standardized based on work of by Joseph Whitworth. This was known as British Standard Whitworth, but was replaced by other standards in the late 19th century.

Railroad track gauge was standardized so that rail cars and locomotives could operate on track of various railroad companies. Before standardization it was necessary to unload and reload freight at every change of gauge.

Pipe sizes

Shoe size standardization was made easier by the Blanchard pattern lathe which could make nearly identical copies of the wood lasts on which the shoes were held and shaped. Standard lasts enabled a manufacturer to make standard shoe sizes.

The screw base size and thread dimensions of electric lamp bulbs was standardized by Thomas Edison.

Electrical voltage and frequency

Electrical wiring and device standards

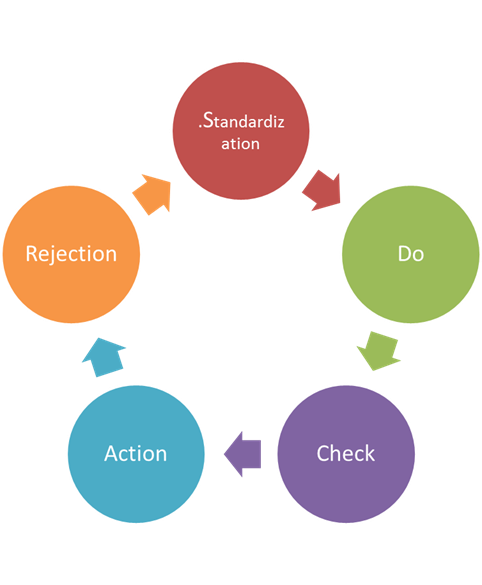

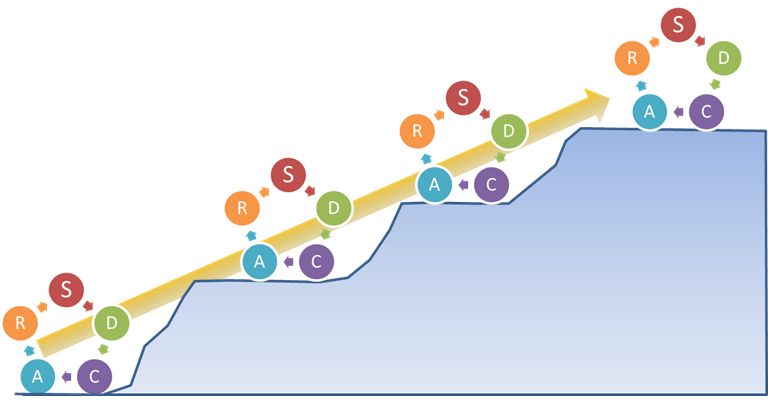

standardization & Kaizen

Standardization is the result of the improvement(kaizen)

and Standardization is the starting point for the next improvement

*Qutote from Wikipedia