Automation with human touch

What is Jidoka?

Jidoka means providing machines and operators the ability to detect when an abnomal situation has occurred and immediately stop work to institute countermeasures.

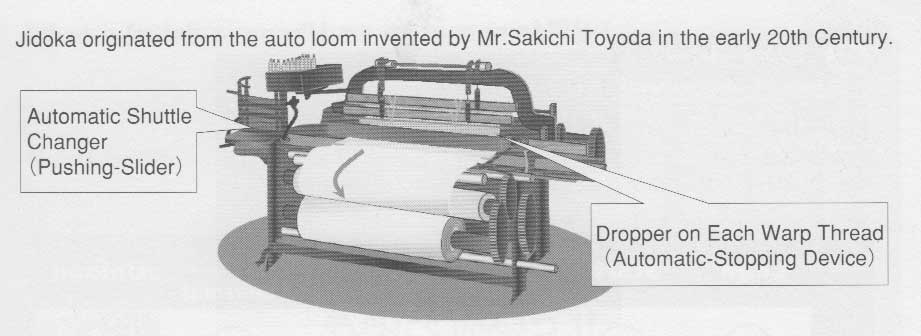

The term jidoka used in the TPS (Toyota Production System) can be defined as “automation with a human touch.” The word jidoka traces its roots to the invention of the automatic loom by Sakichi Toyoda, Founder of the Toyota Group. The automatic loom is a machine that spins thread for cloth and weaves textiles automatically.

Before automated devices were commonplace, back-strap looms, ground looms, and high-warp looms were used to manually weave cloth. In 1896, Sakichi Toyoda invented Japan’s first self-powered loom called the “Toyoda Power Loom.” Subsequently, he incorporated numerous revolutionary inventions into his looms, including the weft-breakage automatic stopping device (which automatically stopped the loom when a thread breakage was detected), the warp supply device and the automatic shuttle changer. Then, in 1924, Sakichi invented the world’s first automatic loom, called the “Type-G Toyoda Automatic Loom (with non-stop shuttle-change motion)” which could change shuttles without stopping operation.

The Toyota term “jido” is applied to a machine with a built-in device for making judgments, whereas the regular Japanese term “jido” (automation) is simply applied to a machine that moves on its own. Jidoka refers to “automation with a human touch,” as opposed to a machine that simply moves under the monitoring and supervision of an operator.

Since the loom stopped when a problem arose, no defective products were produced. This meant that a single operator could be put in charge of numerous looms, resulting in a tremendous improvement in productivity.

Comments