- Static Electricity Control

- Pasting conductive sheet

- Electrostatic measures of chair and chair cover

- Mounting location of the ground wire

- Humidity, temperature measurement

- Humidity control and temperature control

- Control position of the wristband

- Wiringthe Ground Wire

- Ground of shelf

- Trolly

- Antistatic tape

- Antistatic with aluminum foil

- Trash Change into metal

- Improved handling of earth strap

- Antistaticusing theionizer

- Using conductive material container

Static Electricity Control

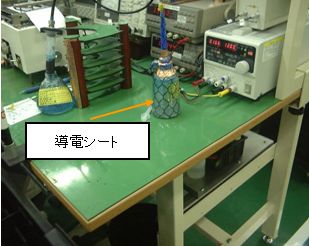

Pasting conductive sheet

In order to preventcharging of theplasticcover, and then paste the conductive sheet

Electrostatic measures of chair and chair cover

Working chair used in the assembly processis required against static electricity discharge

same chair cover

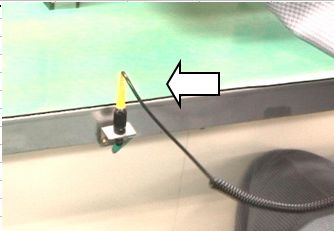

Mounting location of the ground wire

Securely attached to the mounting of the ground wire

To prevent poor contact periodically to check

Poor contact problems can be reducedby attaching a wrist strapchecker

Humidity, temperature measurement

Measuring the temperature and humidity of each point of the process

Measurement data to fill in the check table at the site

Because it is immediately notice dunusually

Note: Recommended specificationsin the clean room

Humidity:60±20%

temperature:23±5℃

Humidity control and temperature control

Humidifier

Control position of the wristband

Wiringthe Ground Wire

Done as shown in the picture below

( Winding wire is NG)

Ground of shelf

Ground product, shelf,trolly with chain

Trolly

Use the stainless steel trolley

Antistatic tape

Antistatic tape to reduce thecharge

Antistatic with aluminum foil

Trash Change into metal

Becouse it is untistatic

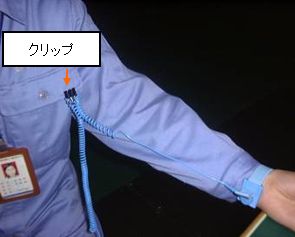

Improved handling of earth strap

Clip as shown in the picture

Antistaticusing theionizer

Using conductive material container

Comments