eliminating Waste thoroughly

In these methods, they identified 3 general forms of waste, which they called in Japanese – ‘Muda‘ (meaning unproductive), ‘Mura‘ (unevenness, inconsistency) and ‘Muri‘ (over-burden, unreasonableness). In doing this, they also identified 7 particular types of waste in manufacturing:

Seven WaStes

Mr Taiichi Ohnols categorization of the seven major wastes typically found at any gemba (workplace)

Overproduction

Producing mores sooner or faster than is  required by the next process or customerl

required by the next process or customerl

Waiting

Operators standing idle as machines cyck  equipment faiIS parts delay etc.

equipment faiIS parts delay etc.

Conveyance

Conveyance itself is waste because it creates  no value. Obviously parts and products must be transported, but any movement beyond the absolute minimum is MUDA.

no value. Obviously parts and products must be transported, but any movement beyond the absolute minimum is MUDA.

Processing(or Overprocessing)

Unnecessary or incorrect processing.

Inventory

Keeping unnecessary raw materiais, parts, WIP (work in processj)and finished goods. More precisely,keeping more than the minimum stock necessary for a well-controlled pull system.

WIP (work in processj)and finished goods. More precisely,keeping more than the minimum stock necessary for a well-controlled pull system.

Motion

Operator making movements that is creating  no value.We can also identify waste in the motion of machines.

no value.We can also identify waste in the motion of machines.

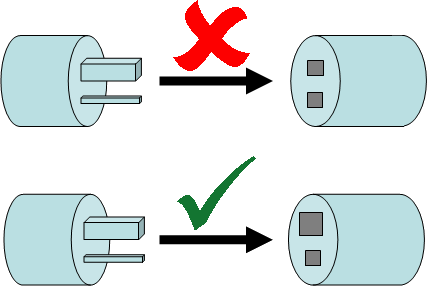

Correction

lnspections, rework and scrap.

Comments