Plant Management

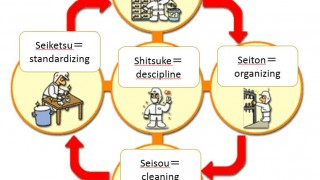

Plant Management 1-9 Standardization

StandardizationEverything surrounding us, if left uncontrolled, will be out of rules and become chaotic.Therefore,there ...

Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

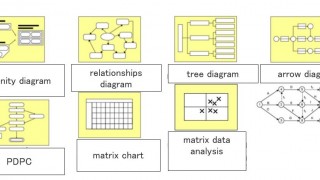

Plant Management  TPS dictionary

TPS dictionary