Plant Management

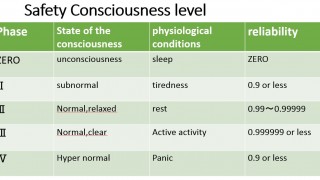

Plant Management 2-2 Safety Consciousness level

Safety Consciousness levelThe unsafe behavior occurs by the carelessness of working person, but the carelessness is not ...

Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management  Plant Management

Plant Management