Low cost Facility and improvement

Low cost development of facility is important besides advanced system development with sophisticated sensors robots.

The ability to select right material and processing method during the facility life cycle is important. For this purpose you should classify process technology.

For example, fusing technology. there are such methods as welding,brazing, friction-

welding, corking bonding, riveting, and bolt-fastening. Which technology to be used for easy and low cost disassembling, for example?

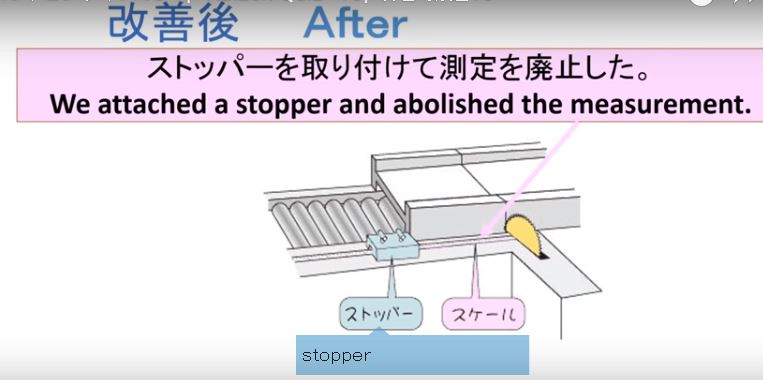

The basic philosophy of low cost Facility can be realized by combining simple-function

machines by simple mechanism.

The topic of low cost automation is getting popular overseas.

Conventionally, Value-Engineering/Value-Analysis has been applied from product planning stage (Zero-Look VE), to design stage (First-look VE) and to manufacturing stage (Second-look VE) and has produced a significant good results. However ,Importance of simple mechanism using conventional gears, springs and links without using sophisticated sensors is becoming more important as they applied to advanced machines .

Related terms:

In-house making of Facility ,LCC, CD design, VE/VE activity Simple mechanism applied

Facility Mistake proof Facility,even big loss improvement of Facility.

Comments