Training for Maintenance

The training for maintenance is different from other technical training in that that it

requires wide range of skills covering mechanical electrical and chemical fields.

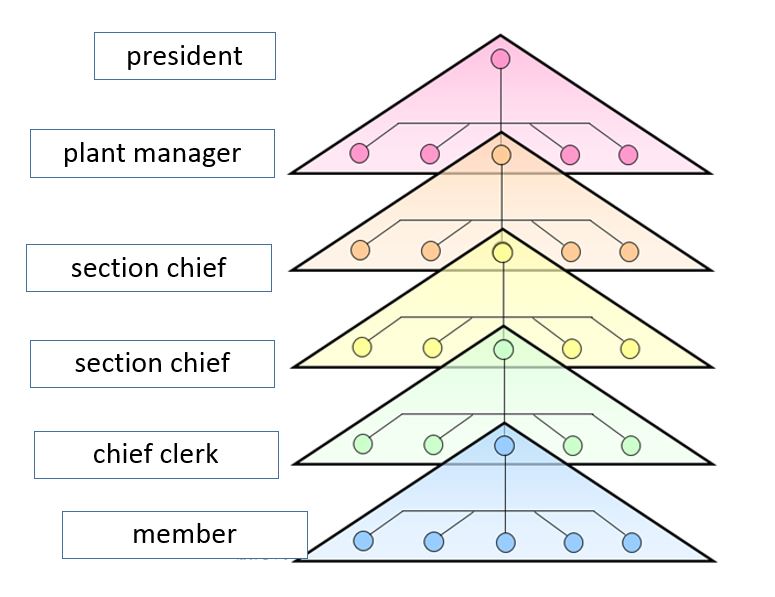

It is also necessary to train leadership and management skill to cooperate with process engineers to develop new facility.

To train repairing skill it is necessary to train the method to detect troubles. measure and analyze existing conditions. replace or fabricate parts,trial operation and tuning.

It is necessary to train five senses in order to detect troubles by temperature ,vibration and abnormal sounds.

For instance, sound probing rod is used to detect wearing conditions of bearings.

if you can understand these sound and measured vibration data. then you can more

accurately judge the condition. which all requires a long experience.

In order to train and transfer these skill OJT is the most important.

In addition you should set up centralized training room where you prepare cut models for broken parts and units You should train how to detect trouble and repairing of You should review repairing process and time in order to look for the optimal method.

While training, it is necessary to make arrangements of spare parts by skilled maintenance

staff in advance. It is also necessary to pay attention to safety and judge whether additional helping hands is required By way of such training you can naturally develop leadership and management skill with less waste.

Related teams:

Failure detecting techniquct Repair technique,Measurement and analysis technique,Management technique Training occasion

Comments